Product : Sapphire

A sapphire is a single crystal grown with alumina (Al2O3)at a temperature above 2,050℃. In a similar way, sapphire wafer is a sapphire single crystal cut and polished by diameter to make it suitable for GaN Epi process for LEDs.

Wafers are core materials that affect the light efficiency of LED chips according to the level of processing. They are used in LED chips found in BLUs in TVs and mobile devices, lighting, electronic signboards, traffic lights and automobile lighting.

It is expected to expand its use as a micro LED, attracting attention as a next generation display technology. Micro LED is miniaturized to a 1/50 scale compared to existing LEDs reduces power consumption by 20% compared to OLED. It will increase rapidly to wearable display applications for Virtual Reality (VR) and Augmented Reality (AR) in the microdisplay market.

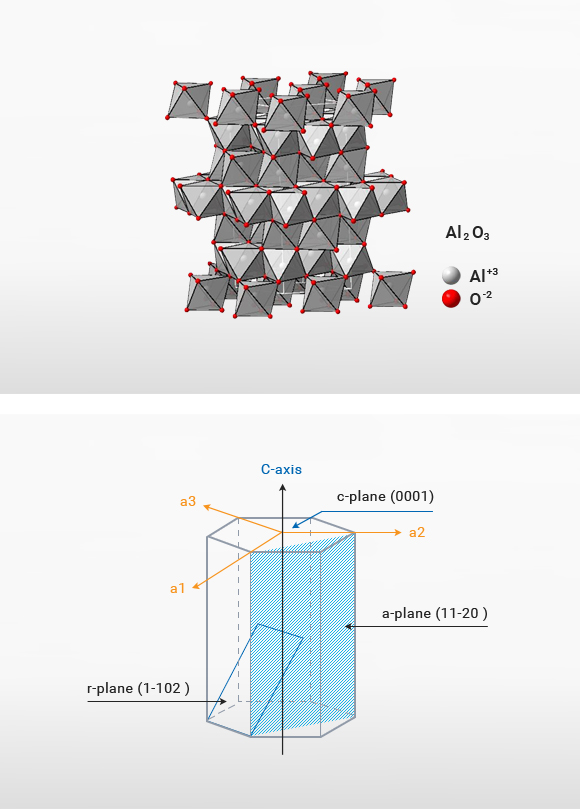

- What Is A Sapphire Single Crystal?

- This material grows into a single crystal structure from melting alumina (Al2O3), which is a compound of aluminum (Al) and oxygen (O), at temperatures higher than 2,050℃ before then solidifying.

Click on the right button to view a large image.

- The Strongest Hardness

On Earth After Diamonds - Sapphire single crystals have the strongest hardness on Earth after diamonds. They are about 10 times higher in abrasion resistance and corrosion resistance than quartz, and have excellent insulating characteristics and optical transparency.

Click on the right button to view a large image.

| Physical Properties | Value |

|---|---|

| Crystal structure | Hexagonal system (rhombohedral) |

| Unit cell dimension | a = 4.758 Å , c = 12.991 Å |

| Density | 3.98g/cm3 |

| Hardness | 9 mohs, 1,525-2,000 Knoop |

| Tensile strength | 400MPa |

| Flexural strength | 2,500~4,000 MPa |

| Thermal Properties | Value |

|---|---|

| Thermal conductivity (at 300K) | 23.1 W/m·K (perpendicular to c-axis) / 25.2 W/m·K (parallel to c-axis) |

| Specific heat | 105 J/kg·K at 91K / 761 J/kg·K at 291K |

| Thermal coefficient of linear expansion (at 323K) | 6.66?x?10-6 ./K(parallel to optical axis) 5?x?10-6 /K (perpendicular to optical axis) |

| Melting point | 2,050 °C |

| Boiling point | 2,980 °C |

- Comparison Of Sapphire Single Crystal Growth Methods

- Advanced Kyropoulos Growth Method - For this new growth method based on the Kyropoulos growth method developed in Russia, Iljin Display has improved its chamber and insulation structure through its own research and development.

Click on the right button to view a large image.

| Growth Method | VHGF | HEM | Kyropoulos | Advanced Kyropoulos | |

|---|---|---|---|---|---|

| Ingot Size | 2~6inch | 2~8inch | 2~8inch | 2~8inch | |

| Ingot Smoothing | Quality | Good | Good | Excellent | Excellent |

| Bubbles | Moderate | Moderate | Moderate | Good | |

| Lineage | Good | Poor | Good | Excellent | |

| Crystalline | Excellent | Good | Excellent | Excellent | |

| Insulation Property | Excellent | Excellent | Poor | Excellent | |

| Power Consumption | Low | Low | Medium | Low | |

| Man Hour | Moderate | Moderate | Large | Low | |

| Maintenance Cost | Medium | High | High | Low | |

| Productivity | Good | Excellent | Good | Excellent | |

| Manufacturing Cost | Good | Good | Good | Excellent | |

Specifications

Click on the right button to view a large image.

| Property | Unit | 4” | 6” |

|---|---|---|---|

| Diameter | mm | 100.05±0.02 | 150.05±0.05 |

| Orientation | - | c?Plane (0001) a?Plane (11-20) r?Plane (10-12) m?Plane (10-10) |

|

| Orientation Tilt Tolerance | Degree | 0±0.05 | 0±0.05 |

| Flat length | mm | Flat 30.7±0.5 or Notch | Flat 25~50±1.0 or Notch |

| Usable Length | Max 220 | Max 200 | |

| Surface finish | mm | As cored Fine Ground | |

| Crystal Quality | - | No Grain Boundaries, Twins, Lineages, and Crack | |

| Picture | - | 4”, 6” 이미지 | |

- Single Crystal Sapphire Polished Wafer

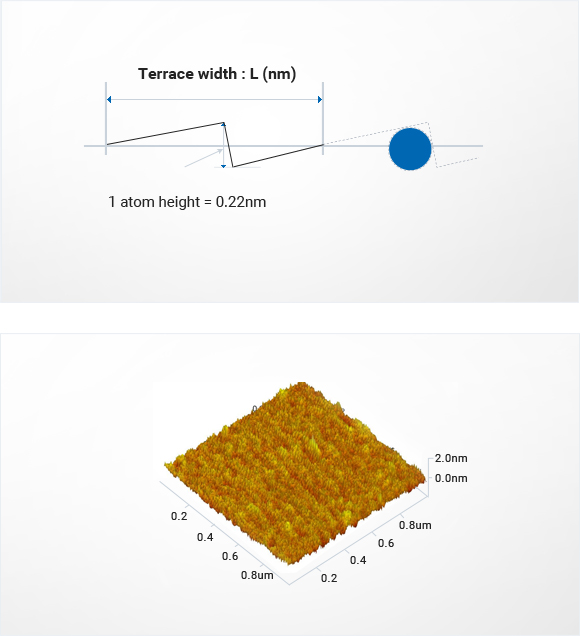

After the extraction of ingots by coring single crystal boules according to the required diameters and orientations, sapphire wafers are cut into the shape of the substrate using diamond wires. The as-cut substrate is uniformly shaped through the edge and lapping processes, and the surface stress is removed through the heat treatment process. The substrate is then polished to a surface roughness of 0.2nm and fabricated to be suitable for the GaN Epi process for LEDs.

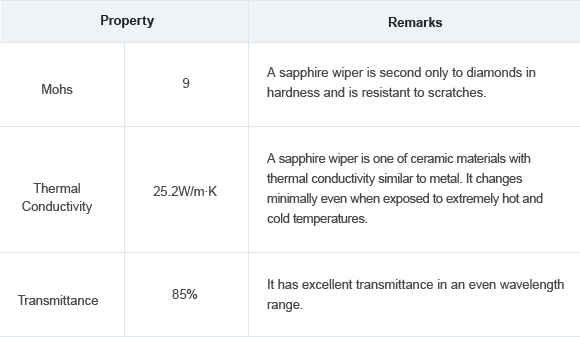

- Second Only To Diamonds In Hardness

Excellence In Abrasion Resistance, Corrosion Resistance,

Insulating Characteristics And Optical Transparency

Click on the right button to view a large image.

| Property | Remarks | ||

|---|---|---|---|

| Mechanical Characteristics | Mohs | 9 | A sapphire wiper is second only to diamonds in hardness and is resistant to scratches. |

| Temperature Characteristics | Thermal conductivity | 25.12W/M/K (100℃) | A sapphire wiper is one of ceramic materials with thermal conductivity similar to metal. It changes minimally even when exposed to extremely hot and cold temperatures. |

| Optical Characteristics | Transmittance | 85% | It has excellent transmittance in an even wavelength range. |

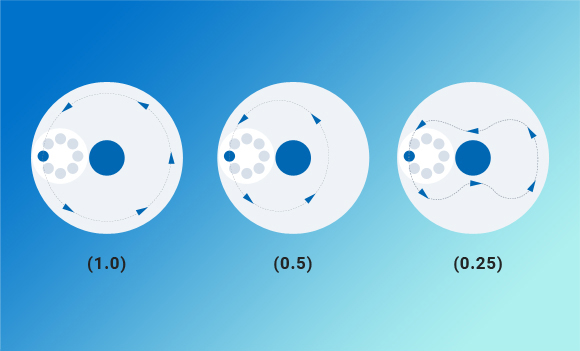

- Optimum Production Design For High Flatness Without Warpage In High-temperature Processing

- To fabricate a high flatness sapphire wafer in the lapping process, the optimal conditions of the vertical and horizontal rotation ratios of the two-sided equipment are designed, and the shape of the substrate is made concentric with uniform processing. These substrates minimize non-uniform bending during the Epi process in high temperature environments.

Click on the right button to view a large image.

In the CMP process, polishing with Nano Silica Slurry is performed to make the surface roughness of the substrate to 0.2nm.

Click on the right button to view a large image.

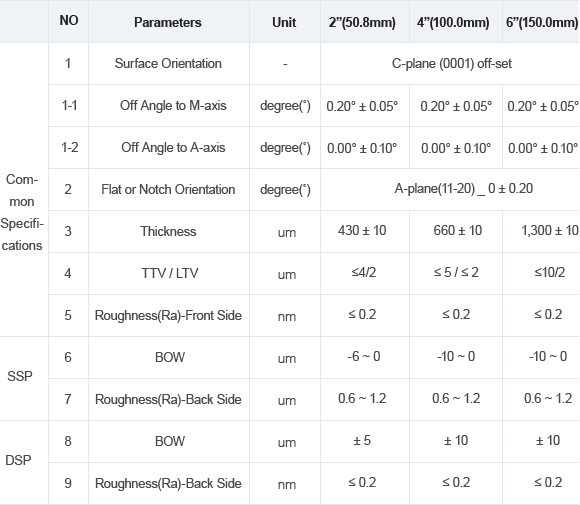

Specifications

Sapphire SSP(Single Side Polished) Wafer

Sapphire DSP(Double Side Polished) Wafer

Click on the right button to view a large image.

| NO | Parameters | Unit | 2”(50.8mm) | 4”(100.0mm) | 6”(150.0mm) | |

|---|---|---|---|---|---|---|

| Common Specifications | 1 | Surface Orientation | - | C-plane (0001) off-set | ||

| 1-1 | Off Angle to M-axis | degree(˚) | 0.20° ± 0.05° | 0.20° ± 0.05° | 0.20° ± 0.05° | |

| 1-2 | Off Angle to A-axis | degree(˚) | 0.00° ± 0.10° | 0.00° ± 0.10° | 0.00° ± 0.10° | |

| 2 | Flat or Notch Orientation | degree(˚) | A-plane(11-20) _ 0 ± 0.20 | |||

| 3 | Thickness | ㎛ | 430 ± 10 | 650 ± 10 | 650 ± 10 | |

| 4 | TTV / LTV | ㎛ | ≤ 5 / ≤ 2 | ≤ 5 / ≤ 2 | ≤ 5 / ≤ 2 | |

| 5 | Roughness(Ra)-Front side | ㎚ | ≤ 0.2 | ≤ 0.2 | ≤ 0.2 | |

| SSP | 6 | Bow | ㎛ | -10 ~ 0 | -10 ~ 0 | -10 ~ 0 |

| 7 | Roughness(Ra)-Back side | ㎛ | 0.6 ~ 1.2 | 0.6 ~ 1.2 | 0.6 ~ 1.2 | |

| DSP | 8 | Bow | ㎛ | ± 5 | ± 10 | ± 10 |

| 9 | Roughness(Ra)-Back side | ㎚ | ≤ 0.2 | ≤ 0.2 | ≤ 0.2 | |

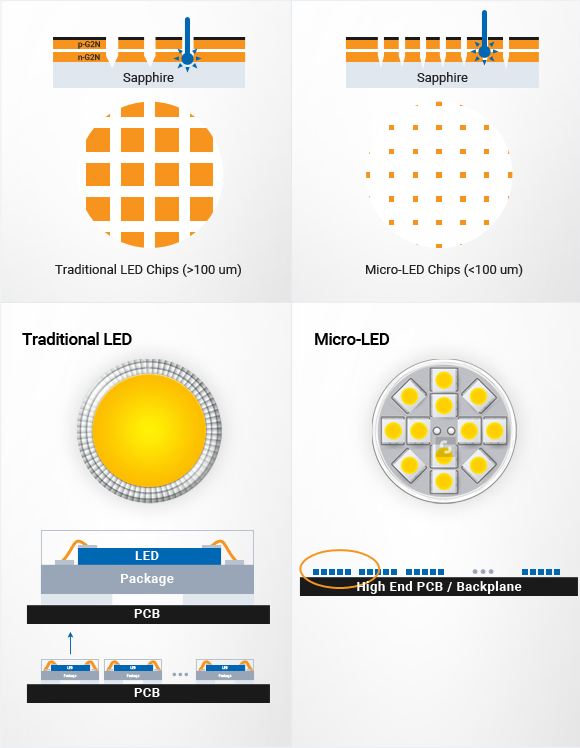

- Next-generation Display

Elements, Micro-LED

In the display business, LED elements with superior power consumption, color gamut, brightness, contrast, life-time and durability are next-generation display elements that achieve chip sizes of less than 100μm compared to conventional LCDs and LEDs. By mounting these micro-LEDs to TFT Backplanes, they are expected to be widely used in Flexible Displays, especially in wearable displays for AR and VR, as well as in medical devices.

Click on the right button to view a large image.

- Sapphire Substrates Required For

Micro-LED Applications

In a micro-LED display, a defect of sapphire significantly affects the chip transference number. It is thus expected that the physical and characteristic enhancement of the sapphire substrate is required. Based on our business strengths, we are pursuing the development of next-generation display materials with leading domestic and global customers with the goal of achieving superior quality and customer satisfaction by providing the world's highest quality ingots and wafers.

Click on the right button to view a large image.

| Property | Parameters | Unit | 6"(150.0mm) |

|---|---|---|---|

| Flatness Characteristics | TTV / LTV | um | ≤ 4 / ≤ 2 |

| BOW / Warp | um | -6 ~ 0 / ≤ 7 | |

| Appearance Characteristics | Chip, Crack, Pore | - | None |

| Surface Characteristics | Particle, Stain, Scratch | - | None |

- Single Crystal Sapphire Window

- After coring single crystal boules into cylindrical or extracting ingots with brick shapes, sapphire wafers are cut into the shape of substrate using diamond wires. After this, shape processing and double-sided polishing are carried out to make them suitable for each application type and size.

Click on the right button to view a large image.

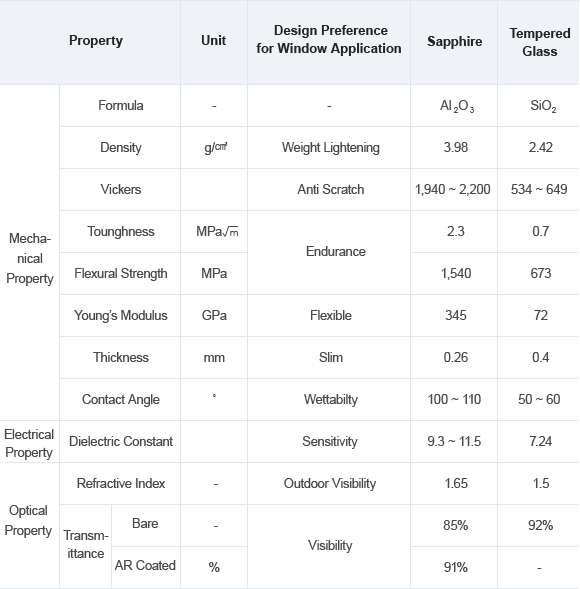

| Property | Design Preference for Window Application | Sapphire | Tempered Glass | ||

|---|---|---|---|---|---|

| Mechanical Property | ★★Material | Al2O3 Anisotropy | SiO2 Isotropy | ||

| ★★Density(9/㎤) | Weight Lightening | 3.98 | 2.42 | ||

| ★★Hardness | Mohs | Anti Scratch | 9 | 7 | |

| Vickers (kg/mm2) | 1,940~2,200 | 534 ~ 649 | |||

| Impact Test(N) | Endurance | 1,060 | 198 | ||

| ★★Bending Test(N) | 1,540 | 673 | |||

| Yong’s Elastic Modulus(GPa) | Flexible | 345 | 72 | ||

| Thickness(mm) | Slim | 0.26mm | 0.4mm | ||

| ★Contact Angle(˚) | Wettability | 100~110° | 50~60° | ||

| Electrical Property | Dielectric Constant | Sensitivity | 9.3 ~ 11.5 | 7.24 | |

| ★★Refractive Index(550nm) | Outdoor Visibility | 1.65 | 1.5 | ||

| Optical Property | ★★ Transmittance | Bare | Visibility | 85% | 92% |

| AR Coated | 91% | - | |||

- Optimized For Manufacturing Various Window Products Thanks To Its High Production Rate And Streamlined Process

Our Substrates Have High Strength From A High-Temperature Heat Treatment.

Our window substrates are optimized for manufacturing various kinds of window products thanks to the high production rate by adopting the simplified process of double-sided polishing technology. In addition, surface roughness and scratch level are equivalent to those of LED products by conducting final polishing on the surfaces with Silica Slurry for LEDs. Although a sapphire can be easily broken by external impact due to its material characteristics, our company performs high-temperature heat treatment so that the substrates are high strength and resistant to impact and breakage.

Click on the right button to view a large image.

- Sapphire Window

Specifications

Click on the right button to view a large image.

| No | Parameters | Unit | Cover Glass | Lens |

|---|---|---|---|---|

| 1 | Thickness | um | ≥ 500 ± 20 | ≥ 300 ± 20 |

| 2 | TV5 | um | ≤ 20 | ≤ 5 |

| 3 | Surface Roughness(Ra) | nm | ≤ 0.5 | ≤ 0.5 |

| 4 | Edge Bevel | um | Customize | |

| 5 | Surface shape | - | ||

| 6 | Surface Round | - | ||

| 7 | Diameter | mm | ||

| 8 | Step Thickness | um |